Nuclear Fittings

Certifications

Standard

Object

Emitted by

Standard

NNSA China qualification for fittings

Object

Products and quality system

Emitted by

NNSA

Standard

ASME III MO

Object

Quality system

Emitted by

ASME

Standard

ASME B31.1, B31.3, B31.4. B31.8, Sect. VIII...

Object

Self-reinforcing inserts and branch outlets for pressurised equipment

Emitted by

TUV

However, manufacturing nuclear fittings requires very high and specific quality control standards. M.E.G.A. has been recognized as an ASME Material Organization, frequently works according to RCC-M standards, and has been approved by the Chinese NNSA, giving us the ability to supply products fully in accordance with the restrictive requirements of the nuclear sector.

With international experience in supplying nuclear fittings, we are able to respond promptly to each customer's needs, even the most specific ones. We take care efficiently and flexibly of the entire production cycle of each nuclear fitting, starting from forging to the final stage of testing and inherent certifications.

- What kind of nuclear fittings can we deal with?

- Available materials

- Why choosing MEGA for nuclear fittings

Types of nuclear fittings

Depending on your needs, M.E.G.A. manufactures and provides you with different types of nuclear fittings. Below you will find a list of our products for nuclear plants with their main characteristics.

Standard nuclear fittings

Standard fittings and unions are high-quality products suitable for the nuclear industry. Threaded or socket fittings, as well as swage nipples, are available in all the variants provided by the standards: threaded, BW, flat, and eccentric.

For nuclear plants, fittings are provided in carbon steel, stainless steel.

Discover our standard fittings

Megalets

Among the branch outlet nuclear fittings, the so-called megalets are the most used products, self-reinforcing branch outlets with a 90° conformation to the main pipeline. Depending on the different configurations, they are divided into:

- Latromegalet: can be installed to obtain a branch outlet with an angle other than 90°;

- Elbowmegalet: can be mounted on a curve;

- Insert megalet: that can be welded directly inside the main pipe.

- All these types can be supplied with butt weld (BW), socket-weld, threaded and also flanged ends.

In order to satisfy the security standards of a nuclear plant, these fittings are required to undergo the certifications we will mention below.

Discover our branch outlet fittings

Special nuclear fittings

This product line includes special tees (e.g. two, three or more branch outlets), special wyes (two, three or more ways, with piggability requirements), special caps, special flanges (e.g. swivel flanges, anchor flanges) and flanged fittings, and many other types of fittings designed and developed according to specific requirements of the nuclear industry.

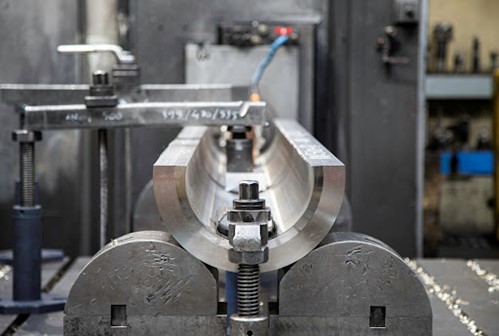

Seamless pipes for nuclear plants

M.E.G.A. is able to produce seamless nuclear fittings up to 11000 mm in length and 1400 mm in outside diameter, specifically designed for nuclear plants. The special machining process enables M.E.G.A. to produce special SMLS seamless tubes with extremely small thicknesses (up to 20 mm - depending on other dimensions) and large diameters, available in different materials.

Welded nuclear fittings

We have a special department for welding fittings. Here we make spools and other special assemblies for the nuclear industry, suitable to meet customer requirements with certified nuclear products guaranteed by our quality system. Welding can be performed on all machined products (inside/outside of forgings, ring joint seats of flanges, etc.).

Available materials for nuclear applications

MEGA manufactures nuclear-grade fittings in a wide range of steels and alloys engineered to withstand the extreme operating conditions typical of nuclear power generation. Materials include carbon steels, low-temperature carbon steels, high-yield steels, Cr-Mo alloy steels, stainless steels, duplex and super duplex steels, SMO F44, nickel alloys, and titanium, all supplied according to customer specifications.

These materials offer several advantages when addressing nuclear-sector challenges:

-

Outstanding resistance to corrosion and stress-corrosion cracking, ensured by high-alloy stainless steels, duplex/super duplex grades, and nickel-based alloys—critical in primary and secondary cooling circuits exposed to aggressive media.

-

High mechanical strength at elevated temperatures, delivered by Cr-Mo alloys, SMO grades, and nickel alloys, enabling safe operation under severe thermal cycles and pressure peaks.

-

Dimensional stability and fatigue resistance are essential for components exposed to flow-induced vibration (FIV) or thermal transients, particularly in heavy-wall tees, outlets, reducers, and forged pipes designed for nuclear service.

-

Full traceability and compliance with nuclear standards, supported by MEGA’s integrated forging facility certified to ISO 9001:2008 and ASME NCA-3800, ensuring complete control from raw material to finished product.

This combination of materials and rigorous process control guarantees the long-term performance required for safety-critical nuclear infrastructure.

Why choosing MEGA for nuclear fittings

For over 60 years, MEGA has been a trusted partner for nuclear operators and EPC contractors worldwide, delivering fully customized, high-integrity components for the most demanding environments. Our value lies in a unique mix of engineering expertise, manufacturing depth, and certified quality.

MEGA’s key differentiators include:

-

End-to-end in-house production, from forging to machining, heat treatment, NDE (UT, PT, MT), hydrostatic testing, surface treatments, and final documentation—ensuring complete process control and maximum reliability.

-

Advanced engineering capabilities, including Finite Element Analysis (FEA), design validation, pigging studies, and custom modeling for complex geometries such as heavy-wall tees, Y-pieces, lateral tees, large-diameter reinforced nozzles, forged pipes, and special nuclear fittings .

-

Unlimited custom manufacturing, producing components up to 80” and heavy special forgings up to 40 tons; any steel grade can be engineered to match project-specific requirements.

-

Nuclear-grade certifications and compliance, supported by MEGA’s ASME, RCC-M, EN, and PED manufacturing capabilities, and an accredited internal laboratory (Accredia 17025) for destructive and non-destructive testing, ensuring full conformity with global nuclear codes.

-

Proven expertise in critical applications, supplying complex components for conventional and nuclear power stations, including high-pressure, high-temperature, and vibration-sensitive systems requiring extremely low stress-intensification factors.

With MEGA, nuclear stakeholders gain a partner capable of designing, forging, machining, testing, and certifying every component with utmost precision—delivering long-term safety, consistent performance, and exceptional reliability in all operating conditions.